SP Energy Networks (SPEN): Development of the Real Time Fault Level Monitor

Before getting into the details of Outram’s Real Time Fault Level Monitoring Project with SPEN, we must share that the RTFLM has been chosen as a finalist for the Network 2020 Game Changer of the Year Award!

For Outram the greatest endorsement is having someone else nominate your technology for an award. You can see what SPEN wrote about the RTFLM in their entry submission which we’ve included at the bottom of this page. This is my favourite section:

“RTFLM is a game-changing technology, addressing one of the biggest challenges facing DNOs, with the potential to achieve this at a pragmatic cost.

Early assessments indicate the RTFLM has potential to deliver savings of greater than £25m in SPEN’s two licence areas alone. For example, deployment of a single RTFLM for £30,000, along with complementary technologies such as Active Network Management, could defer replacement of multiple 33kV Ring Main Units (circa £500k each) and/or 33kV circuit breaker boards at Grid Supply Point sites (typically £2m).”

Having collaborated with SPEN to bring the PM7000 FLM to market we are now working together to produce an active, Real Time Fault Level Monitor that will provide reliable fault level measurements every 10 seconds (selectable). This device will be used to calculate prospective Fault Level Currents at LV or MV, both peak and RMS, incorporating Downstream Contribution, for communication to a SCADA system.

Stage 1 of the NIA (Networks Innovation Allowance) Project is well underway, with 2 RTFLM units already delivered to different SPEN sites (October 2018). These units are being installed and tested to ensure they have as little effect on the network as possible. In the short term they will be connected via distribution transformers and the effect on the network studied.

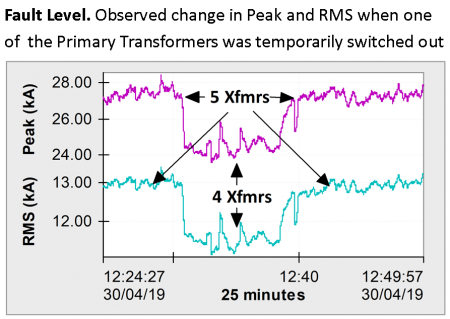

The latest resutls show the real time change in fault level when switching the number of transformers in a SPEN substation.

Once this testing has been completed at 11kV, Stage 2 of the Project is to install further RTFLMs around the UK. This will be to prove the concept that the results obtained can be used to actively manage the network. As part of the initial project agreement with OFGEM, 3 units were to be made available to each UK DNO to join in Stage 2. Several DNOs have already confirmed their anticipated participation.

Network Awards 2020 – Game Changer of the Year Award

Questions

- Outline the purpose of the technology and how it originated

Management of Fault Level (FL) is hugely challenging for Distribution Network Operators (DNOs) worldwide.

It is a critical safety parameter and for SP Energy Networks (SPEN) poses a barrier to the adoption of low carbon technology, and therefore delivery of decarbonisation targets.

FL can be an obstacle to the connection of new Distributed Energy Resources (DER) and has become a decisive factor in determining financial viability of many schemes. Due to unprecedented growth in DER, FL headroom constraints are becoming increasingly prevalent, often requiring major network reinforcement. Although a mature and accepted method of calculating FL exists, static modelling approaches do not give the detail needed to fully exploit available network capacity without extensive capex.

In 2016, SPEN kick-started an innovation project with long-time partner and signal processing experts, Outram Research Ltd (ORL) – a family owned SME. Together they developed a world-first Real-Time Fault Level Monitor (RTFLM).

The safety of electrical networks depends on circuit breakers interrupting supply to affected sections of the grid in the case of a fault. The infrastructure must withstand the currents flowing during the period before the breakers isolate the circuit to prevent destructive failure. Accurately knowing this fault current, which the RTFLM provides, is essential to ensure safety, optimise investment in infrastructure and achieve optimal operation.

Aims of the RTFLM include:

- Providing accurate, real-time, prospective FL measurements from Low Voltage (LV) to 33kV through the application and measurement of small artificial LV disturbances on the network

- Generating FL profiles to identify additional capacity on networks currently constrained by high FL

- Enabling customers to utilise the capacity through flexible connections, without network reinforcement

- Improve network operational safety through providing immediate assessment of FL, enabling switching to restore customers whilst not jeopardising personnel or public safety

- Explain the innovation behind the technology – how does it break new ground?

Installed in network substations, the RTFLM is a standalone cubicle which provides reliable prospective FL readings up to every 10-20 seconds through measurement of small artificial disturbances. This provides high-resolution, real-time network FL information which can be used to release capacity, manage constraints and facilitate DER connection.

It is the first unit capable of producing Peak Make and RMS break prospective FL measurements at 33kV in real-time, including motor contribution. This data can be used for real-time updates to a network’s SCADA system, potentially providing game-changing improvements to network management.

The RTFLM exploits the same processing methodology as pre-existing technology, (the PM7000FLM, manufactured by ORL) but with the addition of a built-in disturbance generator to apply its own artificial load to the network. This overcomes the dependence on naturally occurring disturbances which may or may not be present, reducing the time to produce a quality result from days/weeks to seconds.

- What results has the technology achieved so far and how has it demonstrated benefits for customers, the business and/or other stakeholders?

Development of the RTFLM is seen as a way of freeing up network capacity constrained by FL. DNOs will be able to actively manage the network FL and energy fluctuations through customer use.

Industry practice is to calculate FL using computer modelling tools that consider the network’s construction, configuration, loading and expected fault contribution from commercial and industrial customers. The accuracy depends on the accuracy of the input data, which is not always assured.

Results from real world 11kV and 33kV measurements indicate the RTFLM is very accurate, producing results closer than 1.1% vs well defined models for all key parameters at a 11kV trial in Chester city centre.

The four original transformers on the interconnected substation ring in Chester city centre were struggling to maintain quality and security of supply, particularly as connecting any additional transformers wasn’t previously possible based on the FLs modelled. However, utilising the natural disturbance FL measurement option, the PM7000FLM enabled a fifth to be connected. This resulted in increased quality of voltage supply for outlying customers, improvements in security of supply across the network, and the burden on other local circuits better shared. The alternative to FL measurement would have been to reinforce the network at >£250,000.

Being able to make connection decisions in seconds, using the RTFLM, rather than in ‘slow’ time, will revolutionise network management. Not only will new connections be made where not thought possible before, but customers may be offered flexible connections, with DNOs allowing these on the basis they can temporarily disconnect customers when FLs approach protection limits.

A wider roll out for the artificial disturbance RTFLMs is scheduled for 2020-2021 across SPEN and potentially other UK DNOs at a range of voltages, with the ability to measure the FL across two or even three open points in a single substation. There will also be collaboration with software specialist, Smarter Grid Solutions, which will incorporate RTFLM values into a wider network modelling system, with data integrated into the DNO’s Active Network Management and SCADA systems. Ultimately, the technology saves significant sums of money and aids our low carbon transition.

4) Outline the potential of the technology for making a difference in the sector – how can this be developed further to bring benefit to all?

RTFLM is a game-changing technology, addressing one of the biggest challenges facing DNOs, with the potential to achieve this at a pragmatic cost.

Early assessments indicate the RTFLM has potential to deliver savings of greater than £25m in SPEN’s two licence areas alone. For example, deployment of a single RTFLM for £30,000, along with complementary technologies such as Active Network Management, could defer replacement of multiple 33kV Ring Main Units (circa £500k each) and/or 33kV circuit breaker boards at Grid Supply Point sites (typically £2m).

This will mean freeing up network capacity without causing disruption to the public and network. Use of the RTFLM will bypass the necessity to build new substations, purchase new transformers or cause road closures needed to install additional cable routes – procedures normally required to facilitate the addition of extra network capacity.

The ultimate goal is to see RTFLMs working reliably at 33kV to alleviate major constraints and ensure assets are operated safely in order to facilitate the transition to renewable energy.

SPEN and ORL are proud of this ground-breaking technology. From improved health and safety and operational benefits, to financial and connection improvements, this easily deployable system has the potential to enable impressive change in the sector.