G5/5 vs G5/4 Comparison – Summary Paper

The latest harmonic voltage distortion Recommendation ENA EREC G5/5 now requires measurement of Individual Voltage Harmonics, THD, Voltage Interharmonics and Sub-groups to the 100th order as well as Notching Waveforms, all of which can be measured using Outram’s portable PM7000 or rack-mounted PM7500 power quality analysers with the G5/5 (Enhanced Harmonics) Option.

The portable PM7000 measuring to G5/5 is available for general hire in the UK and worldwide and for sale to Network Operators. For those not familiar with hooking-up power quality analysers, our fully qualified on-site engineers can carry out background harmonic surveys and publish G5/5 reports on the findings comparing the data captured to the planning requirements of the G5/5 Recommendation. Current Harmonics to the 100th are also recorded to enable modelling of additional harmonic sources.

All other models of the PM7000 and PM7500 power quality monitors are available for general sale as well as hire.

The following paper summarises changes made to ENA EREC G5/4 (2005) to produce the new ENA EREC G5/5 document (2020)

Date: 12th November 2020

Report by: Dr Rob Weller (Electrical Investigation Ltd) on behalf of Outram Research Ltd

Contents

What has stayed the same (since G5/4:2005). 4

Updated harmonic voltage (THDV%) limits. 5

Modified planning voltage limits. 6

Updated current emissions limits. 6

Appendix 1 – Assessment procedures. 11

Appendix 2 – Measurement requirements and examples. 15

Verification of compliance (Section 10.9): 17

Connection Queue and concurrent connections (10.10). 17

Harmonic voltage distortion levels (Section 5.1 – Intro): 17

Overview of G5/5 vs G5/4

Harmonic voltage distortion and the connection of harmonic sources and/or resonant plants to transmission systems and distribution networks in the United Kingdom

G5/5 was issued in June 2020, with the following amendments recorded on its cover sheet:

G5/5: Major revision including a full technical rewrite of the standard.

Planning and Compatibility

Section 5 of EREC G5 Issue 5 contains planning and compatibility levels.

Values for planning levels in EREC G5 Issue 5 have been changed in two ways from those in EREC G5 Issue 4:

- The values have been changed to the higher of those in international standards and those in EREC G5 Issue 4.

- The voltage ranges have been selected to better align with voltage levels in use on the GB system.

Values for compatibility levels in EREC G5 Issue 5 have been changed using the same method and justification as used to change the planning levels.

Harmonic above 50th

The values for planning levels and compatibility levels in EREC G5 Issue 5 have been changed from those in EREC G5 Issue 4 to extend the frequency range. The limits now go up to 5 kHz (100th harmonic) rather than the old limits ending at 2.5 kHz (50th harmonic).

Limits for Interharmonics

Limits for interharmonics within EREC G5 Issue 4 have been revised. Based on IEC 61000-4-30 and IEC 61000-4-7, a clear definition for the measurement of interharmonics is given”

Limits for Voltage Notches

Limits for voltage notches have been revised to add an additional requirement on the area of the notch on the voltage waveform.

Stage 1, 2 and 3 Connection Processes

Stage 1 has been completely revised. The revised document has also been written in a more accessible way such that the process of connection should be more understandable for those with limited experience in using standard.

Stage 2 is designed for connection at PCC voltage levels below 33 kV and those assessments that have failed Stage 1. It is also designed in a linear process such that assessments are applied in substages.

Stage 3 uses apportionment of harmonic headroom to set the limits for each connection outlining the minimum requirement for the harmonic specification.

Requirement for compliance

A new section with guidance on how the new user can demonstrate compliance with the limits set by the Network where the new user submits a report confirming compliance with the harmonic specification issued by the NO responsible for the connection.

Concurrent connections

A new section provides guidance on how to set limits for concurrent connections; where multiple new users seek to connect to the same node at the same or to electrically close nodes at the same time.

This paper provides some additional clarity on these points and highlights where the changes will impact assessments or measurements, from the perspective of owners/operators of equipment and that of the network operator.

What has stayed the same (since G5/4:2005)

G5/5 is still the definitive reference used by all network operators (‘NO’s) in the UK to prescribe limits for harmonic voltage distortion and to describe appropriate assessment techniques. It is a DCODE Annex I document (mandatory), requiring all licenced network operators to comply in order to avoid disturbances to other customers.

The general ‘three stage’ assessment approach has remained, in line with G5/4 (and G5/3), but has now been expanded to provide multiple sub-stages. The intention of this is to simplify the assessment process for new connections, although the process now appears more complicated at first glance.

Most of the harmonic limits (for planning and compatibility) remain unchanged, except for higher-order harmonics – these are detailed below. Appendix 3 provides a full list of old vs. new values.

ETR 122 is no longer referenced (“Guide to the application of Engineering Recommendation G5/4 in the assessment of harmonic voltage distortion and connection of non-linear equipment to the Electricity Supply system in the UK”). However, certain parts of its text appear almost verbatim in G5/5, suitably edited/updated with minor changes.

Flicker and unbalance still remain outside the scope of G5/5; reference is made to ENA EREC P28 and P29.

In practice, many smaller connections will pass through Stages 1 or 2 of G5/5 with similar outcomes to G5/4 assessments and without too much headache. However, most larger systems will progress to a Stage 3 assessment, which (given the availability of software packages) is now more comprehensive and onerous than previously.

Summary of changes

The following is a summary of the changes. Additional detail is given in the Appendices below.

Changed Title

G5/5 now includes ‘and/or resonant plant’ in its title, signifying that harmonic assessment may be required when a resonant component (or cable network) is introduced to a network, even if the equipment itself does not produce ‘emissions’ in the conventional sense.

Revised Harmonic Scope

G5/5 now includes consideration of all harmonics up to and including 100th (5kHz), in recognition of the fact that modern equipment can produce disturbing emissions in the range beyond 2500Hz which was the previous G5/4 limit. The limits for these are now generally aligned with European standards.

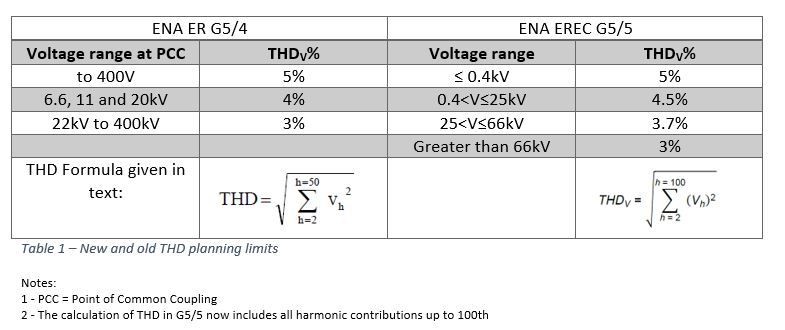

Updated harmonic voltage (THDV%) limits

The limits for harmonic voltage distortion have changed slightly, together with the thresholds (voltage ranges) for assessment. The table below shows this more clearly for total harmonic distortion (THD):

So:

11kV THDV% has increased by 0.5% to 4.5%

22kV THDV% has increased by 1.5% to 4.5%

33kV and 66kV THDV% has increased by 0.7% to 3.7%

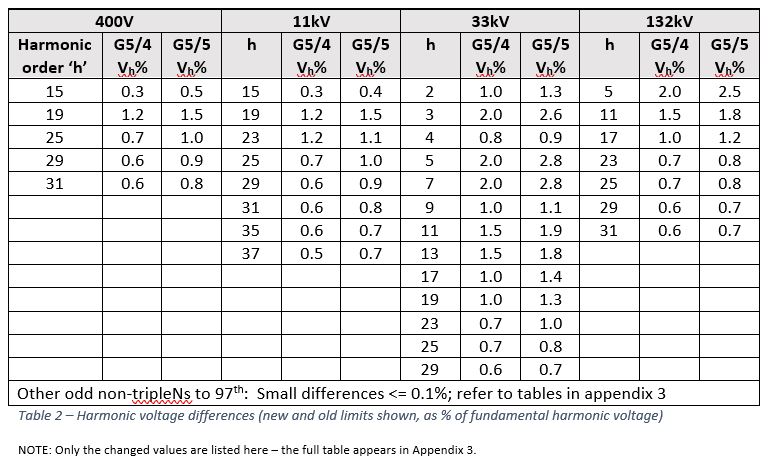

Modified planning voltage limits

The changes to individual harmonic voltage limits have changed (slightly) for the 25th harmonic and higher, also (depending on voltage), there are changes to some lower-order harmonics. The changed values (only) are presented below, shown for common system voltage levels:

Compatibility limits

Compatibility limit tables in G5/5 have also been extended to include 50-100th harmonics, and a similar logic applies to the planning limits.

The THDV% figures are:

- 8% for 33kV and below (no change)

- 4% for 132kV (reduced from 5% in G5/4), and

- 5% for 275kV and 400kV (no change).

There is some deviation between G5/4 and G5/5 individual harmonic voltages at 25kV and above, with some reasonably large reductions for 33kV (e.g. V5compat% reduced from 6% to 5.2%). A full comparison of compatibility limits is not included in this report.

Updated current emissions limits

Current emissions of equipment are relevant in their effect on the voltage distortion that results from the harmonic currents. Essentially, the application of Ohm’s law (using the appropriate system harmonic impedances[1]), together with a correction factor for resonance, gives the resultant change in harmonic voltage distortion that can be assessed at the planning stage.

[1] System harmonic impedances may be calculated, inferred, or measured and are usually provided by the DNO where required.

The currents are also relevant if high tripleN components are present since these currents can result in a large neutral current flow (at LV) and/or give rise to transformer heating.

Harmonic current emissions are given for certain equipment in G5/4 to facilitate the straightforward assessment of smaller connections (Stage 1 or 2), since these currents will give a known voltage distortion on a ‘standard’ system with a known or assumed source impedance. Table 7 of G5/4 gives these values for h≤50, LV, 10MVA. Table 12 gives similarities for 6.6, 11 and 20kV systems. No other mention of harmonic current emissions is made. The figures are derived using assumptions described in ETR 122, including methods for adding current emissions that have now changed for G5/5.

Consequently, G5/5 does not include these tables but does include typical (per unit) emissions for different items of plant in Appendix B, table B.3. These values are used to scale the ‘maximum equipment aggregate power’ that can be connected at different fault levels (SSC), and ultimately this provides the basis for assumptions/simplifications in stage 1 and 2 assessments. Interestingly these tables go only to h=50, but (since the limiting harmonic tends to be 5th, 11th or 37th depending on the assessment technique) this is probably of little consequence.

Terminology

Several new terms are introduced, and many terms are redefined. For example, ‘fault level’ does not appear in G5/5, instead, SSC PCC etc. is used to describe system short circuit power. The result is a document that is more technically correct but lacks the readability of the previous version.

Resonant plant

The need for an assessment, or otherwise for certain types of resonant plant is clarified. It is made clear that power factor correction, long cables, or any other plant that can be considered predominantly capacitive need to be assessed, whether it is emitting harmonics or not.

Resonance was previously only mentioned in G5/4 in the context of a Stage 3 assessment.

A Stage 3 assessment (See Appendix 1) is now required for all resonant plant connected at 33kV and above. A simplified ‘maximum modification’ criterion is presented for lower voltage, theoretically enabling a quick ‘first pass’ assessment with minimal data.

Apportionment multipliers

G5/5 introduces ‘apportionment’ in a similar way to that which may be applied to new connections. The concept of interactive connection requests (concurrent or queued) at the same or nearby nodes is discussed, addressing some of the questions that arose in practice from the application of G5/4.

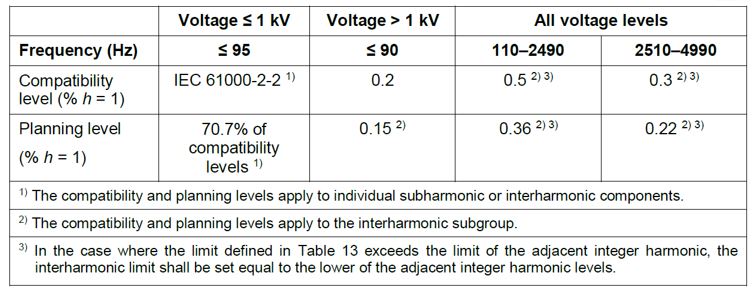

Interharmonics

G5/5 also introduces revised limits for interharmonic voltages; these appear in a new Table 13 as replicated below:

Previously G5/4 made little mention of planning limits for interharmonic distortion other than that equipment with emissions <0.1% of the fundamental voltage could be connected without further assessment, or otherwise up to 0.5% above 90 Hz (G5/4 Table 13).

This clause still exists in G5/5, albeit wordier: “If the predicted voltage interharmonic distortion for individual interharmonic components from a harmonic source is less than 0.1% of the fundamental voltage, then connection may be made without any further assessment of interharmonic voltage emissions…”

G5/5 now includes interharmonics as continuous emissions (rather than under the heading of ‘non-continuous’ as in G5/4). New definitions are introduced for Total Distortion Content TDCV and Total Distortion Ratio TDR. Compatibility at LV (0.4kV and below) and below 90Hz is assessed in relation to flicker, in line with IEC 61000-2-2 (lower ‘beat’ frequencies may be observed).

Interharmonic grouping is discussed, and formulae given (as per IEC 61000-4-30 and IEC 61000-4-7) which are relevant to the measurements and calculations carried out by harmonic voltage analysers.

Short duration bursts

Previously, G5/4 alluded to short-duration bursts (of high harmonic distortion) being generally acceptable and recommended they be accepted on a conditional basis. The implication was that, when assessed against the 95th percentile as in ETR 122, the bursts would give little or no significant impact.

G5/5 (Section 5.5) is now more prescriptive about how these bursts are treated and introduces a short-duration emissions factor ksde which should be used to scale and test emissions against appropriate compatibility limits.

Maximum ratings for soft starters and other semiconductor motor controllers are given (as a function of fault level (or SSC PCC)) so that certain equipment under these ratings can be accepted under Stage 1C-1 or 2A-1 without further assessment.

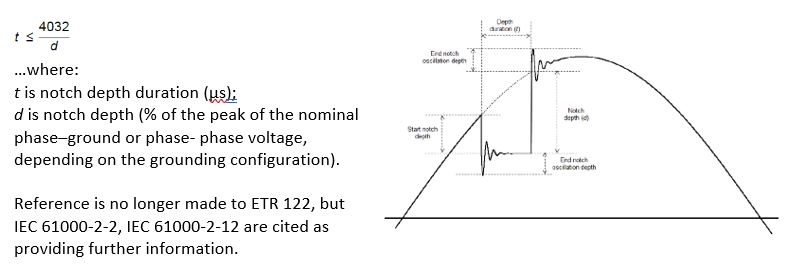

Voltage Notching

Previously, converter equipment that causes voltage notching could be connected if the level of voltage distortion at the PCC is less than appropriate planning levels, and notch depth does not exceed 15% of the peak fundamental voltage. Peak amplitude of oscillations at the start/end of the notch period should also not exceed 10% of the nominal fundamental peak voltage. ETR 122 gave additional guidance.

These requirements still apply, but a definition for acceptable notch duration has been introduced:

Additional parts to G5/5

G5/5 now warns of nonlinearity/transducer error that can occur when trying to measure higher frequencies, with new sub-sections on measurement, instrumentation and transducers under ‘Uncertainty’.

Summing harmonics – average phase displacement no longer fixed at 0 or 90 degrees; formula changed (Sec. 6.3.3) to introduce a new aggregation/diversity factor providing an allowance for intermediate phase angles.

Assessment stages and formulae have been enhanced significantly, with formulae (that were previously in other documents) brought into the main body, or introduced from elsewhere.

Assessment procedures

These have changed – see Appendix 1 below.

Measurement requirements

Harmonic measurements and fault-level measurements are required or can assist with assessments, these are described in Appendix 2 below. The main difference from G5/4 in this regard is the need to consider all harmonics up to h=100, and interharmonics. Note that G5/4 / ETR 122 mentions using 95%ile values from the cumulative probability function, using 3-second and 10-minute characteristics based on IEC 61000-4-30.

G5/5 no longer refers to ETR 122 but does refer to IEC 61000-4-30 and IEC 61000-4-7. ENA EREC G97 is also mentioned. Appendix C.4 states that harmonic compliance assessment shall determine the harmonic voltage distortion, THD, and each harmonic from the 2nd to 100th at the PCC and prove compliance with connection limits.

Various stages of the assessment process require measurements of background harmonic levels, and the need for measurement is now introduced at the latter part of Stage 1 (1D), whereas previously it was limited to Stage 2 or 3 assessments.

G5/5 states that measurements of background harmonic level are needed:

- As part of Stage 1D, 2B, 2C and Stage 3 assessments in order to calculate available headroom for the new user.

- As part of a DNO’s ‘harmonic specification’ prior, to or as part of a Stage 3 assessment

- At remote nodes as part of a Stage 3 assessment (in most cases).

- Synchronised measurements at all relevant nodes are desirable but not essential.

- It is recommended that harmonic measurements be carried out prior to and during the operation of the equipment, to aid compliance modelling and to ensure that emission limits imposed on the connection are met.

Measurements (in the context of Stage 3 assessments) should be based on the 95th percentile (of a ten-minute average characteristic) of at least 7 contiguous days of measurement (longer measurements capturing seasonal trends are preferred, where practicable).

Monitors conforming to Class A requirements in IEC 61000-4-30 (or an equivalent) should be used.

G5/5 states “To reduce uncertainty and facilitate full assessment in accordance with this EREC, it is desirable to have suitable instrumentation for the frequency range up to 5 kHz. Where such instrumentation is not present, NOs may be justified in installing suitable instrumentation where reasonably practicable.

Instruments may group harmonics and interharmonics above 2.5 kHz into 200 Hz bands in accordance with IEC 61000-4-7. Where the instrumentation can be configured to measure individual harmonics above the 50th, it is recommended that this option is selected to facilitate Stage 2C and Stage 3 assessment.

Refer also to Appendix 2.

Appendix 1 – Assessment procedures

General

The 3 stage approach of G5/4 has been embellished to provide an easier route to connection for common types of load, the intention being that these can be ‘fast-tracked’ without specific measurements or calculation in many cases.

However, this approach has added various sub-stages to the simple approach of G5/4, and on first appearance seems to be far more complex.

For connections at LV (where the Point of Common Coupling is LV), start at Stage 1.

For an HV PCC (above 1000V and below 33kV), Stage 2 is applicable.

Stage 3 applies to equipment with a higher voltage PCC, or that which fails stage 2 (excluding LV).

The stages are well summarised in G5/5 Section 6.4 and described in detail in Section 7. The main points are summarised below; note that this text is, in places, a simplification of that in G5/5 and key points may be absent. Refer to the original before undertaking any assessment.

Stage 1(1A to 1D)

Stage 1 is applicable to connections with an LV PCC[1].

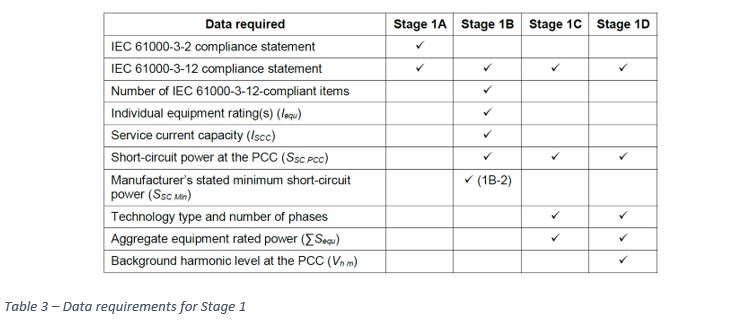

The sub-stages A-D are of increasing complexity. Fewer assumptions are made, and more data is needed as an assessment passes through substages A to D. If a substage is passed, the user can connect the new harmonic load. Table 3 below shows the data required for various stages:

The substages are:

1A: LV Equipment that is rated ≤ 16A per phase, that is compliant with IEC 61000-3-2, EN 61000-3-2, BS EN 61000-3-2, or relevant similar standards, can be connected without further assessment.

Compliance with the standard can be verified by a statement from the manufacturer in their product literature or in the official European Union (EU) Declaration of Conformity, listing the product and compliance with the EN 61000-3-2 standard. If compliance cannot be verified, Stage 1B applies.

If this stage is passed, connection is permitted without referral to the NO.

1B: This stage applies to LV equipment, each rated ≤ 75A per phase, that is compliant with IEC 61000-3-12 or equivalent. Manufacturers must state either “Equipment complying with IEC 61000-3-12”; or “This equipment complies with IEC 61000-3-12 provided that the short-circuit power SSC [denoted SSC Min n herein] is greater than or equal to xx…”

The minimum short circuit power SSC PCC Min must then be ascertained according to Stage 1B-1 or 1B-2 outlined in G5/5. If the network PCC fault level (SSC PCC) exceeds this value then connection is permitted (as per 1A). Otherwise, Stage 1C:

1C: Uses more information relating to the equipment technology type, rated power, and short circuit power level at the PCC. It is only applicable to three phase six or twelve pulse converters, three phase active front end converters, or single phase rectifiers. Background harmonics are assumed <75% of planning level. 1C-1 and 1C-2 describe how to aggregate the contributions. Pass/fail is based on comparison with ‘Permitted Aggregate Equipment Rated Power’ or aggregate Short Circuit Power respectively (Section 7.4 of G5/5). Reinforcement/reconfiguration of the network, or more accurate evaluation of its capacity, may provide a Pass – or move to Stage 1D:

1D: Is a refined version of Stage 1C that takes into account the background harmonic levels to assess whether there is ‘headroom’ for the new connection.

Knowledge (measurement) of certain harmonic voltages is required for 1D, specifically voltage harmonics at different harmonics, depending on converter type. Consideration is made for the following harmonics only:

“Measure the background harmonic level at the PCC (Vh m) for the limiting harmonic orders (h) of h = 5 for three-phase six-pulse converters and three-phase active-front-end converters, h = 37 for three-phase twelve-pulse converters and h = 21 for single-phase rectifiers.”

The maximum permitted aggregate equipment rated power from table 19 is then scaled according to actual fault level, harmonic headroom, and planning levels to determined the permitted aggregate equipment power for the connection.

Stages 1D-1 and 1D-2 differ slightly depending on whether there is a mix of equipment or it is all a similar type, but pass/fail is similar to 1C. Failure advances to Stage 2C.

Stage 2 (2A to 2C)

Stage 2 is applicable to most ‘HV’ (or ‘MV’) connections above 1000V and below 33kV[1].

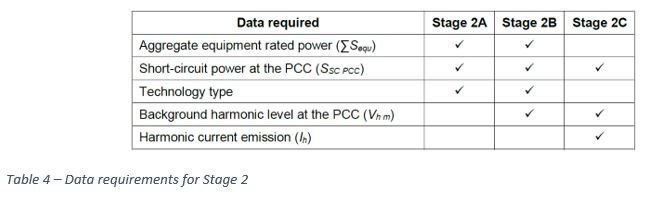

There are now three substages of assessment – Stage 2A through to 2C. The stages increase in complexity going from Stage 2A to Stage 2C.

For connections with an LV PCC that advance to Stage 2, only Stage 2C is applicable.

Table 4 below shows data requirements for stages 2A to 2C:

[1] (It is also applicable to LV equipment with a HV PCC – assessment would normally be carried out at the PCC, but a customer may wish to verify that his/her own equipment does not exceed compatibility limits)

The substages are:

2A: Applies to three phase six pulse, twelve pulse, or active-front-end converters. Background harmonics are assumed to be <75% of planning levels. Assessment is similar to 1C (also having sub-stages 2A-1 and 2A-2) to determine the permitted aggregate equipment power, or minimum short-circuit power requirements at the PCC. If the requirements are not satisfied (i.e. the equipment exceeds the permitted aggregate power, or the network fault level is too low), proceed to 2B.

2B: Requires measurement of background harmonics at the PCC, and is in many ways analogous to method 1D described above. It is applicable to the same equipment as 2A. Knowledge of V h m for h=5 (six pulse or active-front-end converters) or h=11 (twelve-pulse converters) is required, to calculate the harmonic headroom at these assumed limiting frequencies. Pass/fail is based on permitted aggregate power or required short-circuit power (2B-1 and 2B-2 respectively). In case of failure, proceed to 2C:

2C: This assessment uses the actual harmonic current emissions from the equipment, and an assumed harmonic impedance curve, to calculate the voltage distortion from the new connection. It also applies to LV equipment that has failed stage 1. In addition to establishing these current emissions[1], it is necessary to measure the existing background harmonic distortion (to h=100), and to determine the fault-level at the PCC. The resulting voltage distortion (all harmonics and THD) is calculated and compared with planning limits to provide a pass/fail. A fail (above LV) proceeds to Stage 3.

Stage 3

Stage 3 is relatively simple to describe, but far less easy to apply. It applies to all connections at 33kV and above, or to HV connections that have failed 2C.

Essentially the onus is on the network operator that hosts the connection to issue a harmonic specification to the new user, which contains:

- Impedance profile of the PCC in the form of impedance loci or tabular data.

- Background harmonic level(s)

- Limits for incremental harmonic voltages (% h = 1) produced by the new user’s plant or equipment emission at the PCC. This is referred to as Vh Limit Inc

- Limits for resultant total harmonic voltages at the PCC, accounting for the incremental harmonic voltages due to emission from the new user’s plant or equipment and the modification of the background harmonic level. This is referred to as Vh Limit Total.

Data provided from the NO should consider various factors including alternative running arrangements and seasonal trends in demand and generation. An apportionment multiplier may be used to allocate harmonic capacity to different users.

The intention is that a new user shall carry out a harmonic compliance assessment to demonstrate compliance with the limits in the harmonic specification. The purpose of the harmonic compliance assessment is to forecast harmonic levels following the connection of the new relevant equipment, and to determine any harmonic mitigation measures necessary to ensure compliance with the connection limits. This assessment shall be undertaken using an appropriate power system analysis tool. It shall consider the incremental change due to emissions, as well as modification of background levels due to the harmonic impedance (or resonances) of the new user.

The extent of the network considered is at the discretion of the host NO. It may include various nodes remote from the point of connection, which have been identified as likely to suffer due to resonance (harmonic gain factors or ‘transfer coefficients’) or other reasons.

Pass / fail is based on achieving compliance with incremental individual harmonic voltage limits and total harmonic voltage limit. A post-design compliance report shall be submitted to the NO by the new user.

Measurement of background harmonic levels should be carried out before assessment and after connection; the requirements are detailed in G5/5 10.3 and Appendix 2 below. It is recognised that there is some uncertainty in assessment, and conditional connections may be agreed subject to installation of mitigation measures etc. if required. Measurements will help significantly in this regard or in case of any dispute.

G5/5 10.9 states: Compliance with the specified harmonic limits may be verified by harmonic measurements made by the host NO, the User, or their representatives before, during and after commissioning is complete, including full normal operation. The decision as to what measurements are required should rest with the NOs affected.

It is desirable that at least four weeks of harmonic measurement is carried out before the commissioning begins, allowing the background harmonic level of the supply system at the PCC to be established, immediately before the new user is connected to the supply system, prior to connection [and?] during the commissioning stages, which should also be monitored. The continuous monitoring during commissioning, and afterwards, will show the changes that the new user causes at the PCC, for the supply system configuration at the time of commissioning.

Resonant plant

Should be assessed at Stage 3 when connected at 33kV or above. In the case of large solar farms or wind turbine arrays, or other large cable networks, the capacitance of the cables may alter the harmonic impedance of the system, and thus background harmonic levels, significantly. Resonances may also cause issues at other nodes on the network.

A NO may (at its discretion) request a harmonic assessment, at Stage 3, regardless of whether the connected plant emits high levels of harmonics or otherwise.

Items of resonant plant at lower voltages can be assessed using simplified ‘maximum modification’ rules introduced in G5/5; however a ‘fail’ may proceed to Stage 3.

Caveats

For all new loads: Assessment of harmonic and interharmonic frequency components in the frequency range above 2.5 kHz is at the discretion of the host NO.

[1] This would normally be provided by the manufacturer but can be obtained by measurement of similar equipment elsewhere. Worst case values over a range of operating power levels should be used.

Appendix 2 – Measurement requirements and examples

General requirements

G5/5 assessment stages are structured so that small new connections do not require a specific measurement of background harmonics. Typically the need for such increases with the size of the load/generation, or at higher voltage levels.

The responsibility for making these measurements lies with the network operating company, but the customer may be required to assist. Network running arrangements should offer a representative fault level (SSC PCC) at the PCC.

Note that even where a harmonic measurement is not required, there can be a benefit in measuring fault current (SSC PCC) if an assessment with nominal (or DNO provided) figures fails or is marginal. An accurate knowledge of SSC PCC can (at the discretion of the DNO) be substituted into equations and may yield a higher permitted aggregate load (ΣSequ permitted ).

Certain domestic loads (e.g. LED lamps, TVs, Monitors, EVs, Heat Pumps etc.) will give no cause for concern in isolation, nor will they trigger a detailed G5/5 assessment. However, particularly in the absence of ‘linear’ load, the cumulative effect can cause planning limits to be exceeded. It is recommended that DNOs monitor this situation.

Some useful extracts from G5/5 are provided at the end of this appendix.

Examples

The table below gives some guidance. It is anticipated that a new ETR 122 document will be produced in the next year or two, and will provide some worked examples.

Currently there are still some situations that remain unclear (e.g. wide area connection of AC Electric Vehicle Charge Points), since the distorting equipment in question is the vehicle onboard electronics themselves, which may evolve over time. The treatment of situations such as this is still subject of discussion and largely at the discretion of individual network operators.

| Example load | PCC voltage | Assessment stage | Measurement required? | |

| EV Charger 50kVA 3 phase – DC output | LV 400V 3 phase | Stage 1B

Certain equipment (active-front-end) at this rating will automatically qualify under Stage 1C (Table 19) at nominal reference SSC (10MVA), but this cannot be assumed. |

Harmonic measurement required if equipment fails 1B and 1C.

(Measurement of fault level may assist with assessment at Stage 1B and 1C but is not a requirement) |

|

| New housing estate with small single phase heat-pumps at each property, 100 properties, LV point of connection | LV 230V single phase | Input power < 16A/phase means Stage 1A assessment is appropriate for each single item.

If each item is compliant with IEC 61000-3-2, equipment can be connected without further assessment, this is regardless of the number of items.

If the heat pumps are rated at >16A per phase, Stage 1B is appropriate, which also considers number of items and the fault level (SSC PCC) at the PCC.

|

In theory a DNO with knowledge of a higher than normal level of background distortion can request additional consideration of harmonics as part of the connection offer. |

|

| Small pumping station (50kVA) connected to local LV network | LV 400V 3 phase | 50kVA ~ 72A per phase, therefore Stage 1B applies if equipment is controlled by variable speed drives rather than direct online / soft start. | If the equipment has an IEC 61000-3-12 declaration then assess as 1B-1 or 1B-2 as appropriate, otherwise move to Stage 1C. If that fails, measurements for 1D will be necessary. | |

| LV 3 phase 150kVA power factor correction at factory | 400V | Assessed using simplified ‘maximum modification’ rules. | If existing harmonic levels exceed 75% of planning limit, the assessment may fail and proceed to Stage 3, requiring detailed assessment.

It would seem prudent for the network operator to establish the background levels at the PCC prior to assessment. The factory operator may wish to confirm that compatibility limits are not exceeded on his/her system since equipment damage could result. |

|

| Small LV Solar Array, aggregate 500kW | 400V | >75A automatically proceeds to 1C-1 for similar converter types | 1C-1 compares aggregate equipment rated power to the permitted aggregate equipment rated power, using assumptions about the system and knowledge of fault level.

If this fails, harmonic measurement at Stage 1D will be necessary. |

|

| 11kV synchronous generator | 11kV | No assessment required under G5/5 | A synchronous generator is not generally defined as distorting equipment, however a DFIG type machine could be. | |

| 10 MVA solar farm | 11kV | Usually solar inverters will connect at LV, feeding through transformers onto an 11kV or higher voltage system, depending on the size of the array. Since the LV is not shared with other customers, the higher voltage level is the PCC. | For an 11kV PCC, begin with stage 2A-1; this requires knowledge of the fault-level at the POC, normally provided by the network operator.

A large system will usually fail Stage 2A-1, moving to Stage 2B which does require a measurement of background harmonic levels. |

|

| 33kV | The same solar array, connected to a 33kV system or via a dedicated 33:11kV transformer will share a 33kV point of common coupling and will proceed to Stage 3 assessment, requiring measurement of background harmonic distortion. | |||

| 33kV wind | 33kV | Stage 3

A DNO may deem the cable network as ‘resonant plant’, requiring Stage 3 assessment even if the generators are not classed as distorting load. |

Yes – Stage 3 requires harmonic measurements at PCC and (depending on complexity) at Points of Evaluation (PoE) which may include LV network(s).

Measurements should be taken before assessment (to determine background levels), and after connection to validate the assessment.

A measurement of fault level, (or harmonic impedances, if possible) to validate modelled values, can also be advantageous. |

|

Table 5 – Some case studies showing when measurements may be required

Useful extracts from G5/5

The following extracts are taken from G5/5, and appear in the context of measurements. This list is not exhaustive:

Measurement of the background harmonic level (from section 10.3 – in context of Stage 3 assessment):

The background harmonic level at the PCC is measured and included in the harmonic specification. The measurement shall be done according to IEC 61000-4-30 and IEC 61000-4-7 and shall be based on the 95th percentile of at least seven contiguous days of measurement. When three-phase measurement is available, the highest amongst all three phases for each harmonic order shall be included in the specification, along with the total harmonic voltage distortion (THDV). Monitors conforming to Class A requirements in IEC 61000-4-30 should be used.

As part of the Stage 3 assessment it is a requirement to consider remote nodes, so as to ensure that the planning levels at those nodes are not exceeded. The above requirements for the PCC also apply to measurement of the background harmonic level at those remote nodes that are included in the assessment. Synchronised measurement of local (PCC) and remote nodes is desirable but not essential.

Where measurements are not possible, the background harmonic level should be estimated using measurements from electrically adjacent sites. For further guidance on measurements see Clause 6.3.5.

Verification of compliance (Section 10.9):

Compliance with the specified harmonic limits may be verified by harmonic measurements made by the host NO, the User, or their representatives before, during and after commissioning is complete, including full normal operation. The decision as to what measurements are required should rest with the NOs affected.

It is desirable that at least four weeks of harmonic measurement is carried out before the commissioning begins, allowing the background harmonic level of the supply system at the PCC to be established, immediately before the new user is connected to the supply system, prior to connection during the commissioning stages, which should also be monitored. The continuous monitoring during commissioning, and afterwards, will show the changes that the new user causes at the PCC, for the supply system configuration at the time of commissioning.

It must be recognised, however, that an installation could be correctly designed according to a host NO’s harmonic specification and yet result in measured harmonic voltages above the specified limits…

Connection Queue and concurrent connections (10.10)

Once a new user’s installation is commissioned and fully operational, the new user is considered to be part of the background harmonic level and new measurements shall be taken for the next connection application.

Harmonic voltage distortion levels (Section 5.1 – Intro):

Plant and equipment with harmonic and interharmonic emissions above 2.5 kHz is being connected to transmission and distribution networks. It is considered prudent, based on evidence of adverse effects and the establishment of associated compatibility levels in the IEC 61000-2-X series, to manage such emissions, where reasonably practicable. Harmonic assessments should be carried out on harmonic and interharmonic emissions up to 5kHz, however it is recognised that this may not always be practicable in which case assessments may be carried out to only 2.5kHz at the discretion of the NO. In any such assessments, it is at the discretion of the relevant NO to define the harmonic limits and background harmonic level.

Measurement (Section 6.3.5)

Measurements of the background harmonic level on the supply system form part of Stage 1D, Stage 2B and 2C and Stage 3 assessments in order to calculate the available headroom for the new user.

For Stage 2B and 2C assessment, measurements are required at the PCC. For Stage 3 assessment, measurements are required at the PCC and at remote nodes within the affected part(s) of the supply system.

These nodes could be at any voltage level and on part(s) of the supply system not owned or operated by the host NO. The selection of these remote nodes will be dependent upon the outcome of system studies identifying problematic transfer gains. It is recommended that harmonic measurements be carried out prior to and during operation of the connection of the relevant equipment. This will aid compliance monitoring and ensure that the harmonic emission limits imposed on the connection are met.

Instrumentation (Section 6.3.5.1)

Instruments for harmonic measurement are usually power quality monitors.

For harmonic measurements, IEC 61000-4-30, which makes reference to the algorithm described in IEC 61000-4-7, details three classes of accuracy for measuring harmonic components: Class A, Class B and Class S. For the purpose of connection assessment and compliance monitoring, it is recommended that the NO uses a Class A device for measurement of the background harmonic level and for pre- and post-commissioning monitoring.

Based on IEC 61000-4-30, a ten-minute average characteristic should be measured and the weekly 95th percentile value from the cumulative probability function should be used in the assessment process. The use of alternative aggregation periods according to the continuity of the connection’s emissions is considered in Clause 5.5.

To reduce uncertainty and facilitate full assessment in accordance with this EREC, it is desirable to have suitable instrumentation for the frequency range up to 5 kHz. Where such instrumentation is not present, NOs may be justified in installing suitable instrumentation where reasonably practicable.

Instruments may group harmonics and interharmonics above 2.5 kHz into 200 Hz bands in accordance with IEC 61000-4-7. Where the instrumentation can be configured to measure individual harmonics above the 50th, it is recommended that this option is selected to facilitate Stage 2C and Stage 3 assessment.

Transducers (Section 6.3.5.2)

Voltage transducers (VTs) are necessary when performing harmonic and interharmonic measurements at voltages above LV. For LV, it is possible to connect measuring devices directly.

VTs are typically voltage transformers, which form part of metering or protective relay circuits. VTs available on the UK supply system are typically of the electromagnetic (wound) type, capacitive voltage divider type or resistive–capacitive voltage divider type. All transformers have their limitations in terms of frequency response and careful consideration needs to be given to their suitability for harmonic assessment.

Some MV electromagnetic VTs have suitable frequency response up to 5 kHz. EHV electromagnetic VTs have limited frequency response, while resistive–capacitive voltage dividers have a suitable frequency response up to hundreds of kHz. The lower section of a capacitive voltage divider generally comprises a capacitor in parallel with an electromagnetic VT. This arrangement is tuned to 50 Hz and is not suitable for harmonic measurements. However, capacitive voltage dividers can be modified with ring-CTs on the earth links of the lower capacitor and electromagnetic VT in such a way as to extend the suitable frequency response to tens of kHz when necessary.

To reduce uncertainty and facilitate full assessment in accordance with this EREC it is desirable to have suitable transducers for the frequency range up to 5 kHz. Where such transducers are not present, or their suitability is uncertain, NOs may be justified in establishing their suitability or installing suitable transducers where reasonably practicable.

Appendix 3 – Old vs New Planning limits tables

Values in the table below are expressed as % of V1 fundamental voltage

| Harmonic order | 400v | 11kV, 6.6 and 20kV | 33kV | 132kV | ||||

| G5/4 | G5/5 | G5/4 | G5/5 | G5/4 | G5/5 | G5/4 | G5/5 | |

| 2 | 1.6 | 1.6 | 1.5 | 1.5 | 1.0 | 1.3 | 1.0 | 1.0 |

| 3 | 4.0 | 4.0 | 3.0 | 3.0 | 2.0 | 2.6 | 2.0 | 2.0 |

| 4 | 1.0 | 1.0 | 1.0 | 1.0 | 0.8 | 0.9 | 0.8 | 0.8 |

| 5 | 4.0 | 4.0 | 3.0 | 3.0 | 2.0 | 2.8 | 2.0 | 2.5 |

| 6 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| 7 | 4.0 | 4.0 | 3.0 | 3.0 | 2.0 | 2.8 | 2.0 | 2.0 |

| 8 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| 9 | 1.2 | 1.2 | 1.2 | 1.2 | 1.0 | 1.1 | 1.0 | 1.0 |

| 10 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| 11 | 3.0 | 3.0 | 2.0 | 2.0 | 1.5 | 1.9 | 1.5 | 1.8 |

| 12 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 13 | 2.5 | 2.5 | 2.0 | 2.0 | 1.5 | 1.8 | 1.5 | 1.5 |

| 14 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 15 | 0.3 | 0.5 | 0.3 | 0.4 | 0.3 | 0.3 | 0.3 | 0.3 |

| 16 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 17 | 1.6 | 1.6 | 1.6 | 1.6 | 1.0 | 1.4 | 1.0 | 1.2 |

| 18 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 19 | 1.2 | 1.5 | 1.2 | 1.5 | 1.0 | 1.3 | 1.0 | 1.0 |

| 20 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 21 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 22 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 23 | 1.2 | 1.2 | 1.2 | 1.1 | 0.7 | 1.0 | 0.7 | 0.8 |

| 24 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 25 | 0.7 | 1.0 | 0.7 | 1.0 | 0.7 | 0.8 | 0.7 | 0.8 |

| 26 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 27 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 28 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 29 | 0.6 | 0.9 | 0.6 | 0.9 | 0.6 | 0.7 | 0.6 | 0.7 |

| 30 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 31 | 0.6 | 0.8 | 0.6 | 0.8 | 0.6 | 0.7 | 0.6 | 0.7 |

| 32 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 33 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 34 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 35 | 0.6 | 0.7 | 0.6 | 0.7 | 0.6 | 0.6 | 0.6 | 0.6 |

| 36 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 37 | 0.5 | 0.7 | 0.5 | 0.7 | 0.5 | 0.6 | 0.5 | 0.6 |

| 38 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 39 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 40 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 41 | 0.5 | 0.6 | 0.5 | 0.6 | 0.5 | 0.6 | 0.5 | 0.6 |

| 42 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 43 | 0.5 | 0.6 | 0.5 | 0.6 | 0.5 | 0.5 | 0.5 | 0.5 |

| 44 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 45 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 46 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 47 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| 48 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 49 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| 50 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 51 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 52 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 53 | 0.4 | 0.5 | 0.4 | 0.5 | 0.4 | 0.5 | 0.4 | 0.5 |

| 54 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 55 | 0.4 | 0.5 | 0.4 | 0.5 | 0.4 | 0.5 | 0.4 | 0.5 |

| 56 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 57 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 58 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 59 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.5 | 0.4 | 0.5 |

| 60 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 61 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| 62 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 63 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 64 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 65 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| 66 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 67 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| 68 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 69 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 70 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 71 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| 72 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 73 | 0.4 | 0.3 | 0.4 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 |

| 74 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 75 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 76 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 77 | 0.4 | 0.3 | 0.4 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 |

| 78 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 79 | 0.4 | 0.3 | 0.4 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 |

| 80 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 81 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 82 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 83 | 0.4 | 0.3 | 0.4 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 |

| 84 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 85 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.3 | 0.4 |

| 86 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 87 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 88 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 89 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.3 | 0.4 |

| 90 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 91 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.3 | 0.4 |

| 92 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 93 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 94 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 95 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.3 | 0.4 |

| 96 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 97 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.3 | 0.4 |

| 98 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 99 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 100 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| THD: | 5% | 5% | 4% | 4.50% | 3% | 3.70% | 3% | 3% |

© Electrical Investigation Ltd