Ranger PM7000 Power Quality Analyser

Power quality, harmonics to G5/5 (to the 100th), flicker and waveforms monitor.

The Power Master 7000 is a user-friendly, comprehensive, compact and cost-effective power quality monitoring and trouble-shooting unit.

Request a quoteAbout the PM7000

Highly commended in the Electrical Industry Awards 2009, the Power Master 7000 is a user-friendly, comprehensive, compact and cost-effective power quality monitoring and trouble-shooting unit.

It offers virtually everything needed to monitor and record power for surveys and audits. It includes 4 voltage input channels capable for measuring 0 to 600 Vac and 4 current input channels for use with voltage output current clamps, or Rogowski Coil sensors supplied. Twelve pre-stored connection configurations are set for 3 phase, 2 phase and single phase measurements. Users can also configure their own set-up and math calculation requirements and save them to non-volatile memory.

The PM7000 complements the Adaptive Store function with intelligent Waveform Capture. This real-time, auto-ranking mechanism is able to track and rank multiple categories of transient and other problem event types. It discards smaller events when larger ones occur, which means the best, most revealing events are captured without any prior knowledge of what might happen – and without wasting store, and without any re-arming time. This makes the whole waveform capture process sensitive/generous/sensible, abstemious and efficient instead of profligate – so data transfer, storage and search times are minimised. Like the benefits of Adaptive Store, these are also achieved without setting any thresholds! The PM7000 can also measure all the harmonic requirements of the EREC G5/5 recommendation.

Key Features Include

- Cat IV 600V Phase A powered Power Quality Analyser.

- Flicker measurements to IEC61000-4-15: Instantaneous Flicker Sensation, Short Term and Long Term Flicker Perceptibility.

- Single Cycle Adaptive Storage™ recording process provides extremely high resolution over long recording periods.

- 32 Troubleshooting channels with single cycle detail.

- General Parameters: Over 470 channels which record automatically for reporting to the Standards.

- Auto-Ranking Waveform Capture: High speed waveform capture ranked for disturbance severity, 7 types of disturbance captured: Transients, falls (sags), rises (surges), rings, notches, THD, Total Harmonic Value. No thresholds need to be set.

- Harmonics to the 50th (standard): THD and individual harmonics to the 50th as standard. As well as using the 32 detailed recording channels, record 1-50th harmonics on all voltage and current channels in General Parameters every measuring session (400 parameters).

- Interharmonics and individual harmonics to the 127th (optional): As well as using the 32 detailed recording channels to record individual harmonics up to the 127th, record the 1-100th harmonics all at the same time on either 4 voltage or 4 current channels in General Parameters.

- Advanced Harmonics and Interharmonics Option: Automatic and simultaneous measurement of harmonics*1 to the 100th on 6 inputs (V & I), and to the 50th on remaining 2 inputs as well as individual inter-harmonics between fundamental and second harmonics and inter-harmonic sub-groups to the 100th (3 x V only). Individual harmonics, inter-harmonics, groups and sub-groups to the 127th harmonic on any phase can also be measured on detailed Adaptive Store channels. THD and THC also available to the 100th Harmonic.*1 As required by the EN61000-4-7 and G5/5 Standards, harmonics recorded as General Parameters are Harmonic sub-groups comprising the Root Sum Square of the harmonic itself plus the two adjacent 5 Hz lines.

- Supports ENA Recommendations G5/4 and G5/5

- Bi-colour, status LEDs, externally visible, show recording/memory/voltage/power conditions.

- Bluetooth, Ethernet, USB, USB Flash Drive connectivity.

- Comes with Pronto for Windows software, a highly regarded data recovery and analysis package.

- Hook-Up Checklist with photos and reference vector diagrams to give confidence of correct hook-up whether 1st or 101st time of using the unit. 3 versions are available to distinguish between European Union, USA and Asian (Australasian) phase colours. (NB these checklists will open in a new window.)

- Configuration Guide lists in detail the 12 pre-stored configurations in the logger and shows how to set-up the PM7000 to get live recordings in just 15 minutes.

Technical Information

Input Voltage:4 input channels. 0-600Vac or 0-1000Vac (if internal AC power supply disconnected). Sensors: In-line shrouded 4mm banana sockets. Fused voltage leads, crocodile clip.

Input Current: 4 input channels. Sensors: Two ranges on two types. Menu Selectable Rogowski coil 0-6000A, 0-400A, or Voltage Type 0-1 Vac. Safety BNC Socket. Phase reversal in software.

Five distinct simultaneous Recording Systems:

Waveform capture: High Speed sampling on all inputs.

Troubleshooting: Utilising the patented single cycle Adaptive StoreTM to capture comprehensive detail over long recording periods on up to 32 selected parameters.

General Parameter Analysis / Trends: > 470 parameters recorded automatically and simultaneously enabling reporting to recognised Standards.

RMS Event Database: Monitoring for ‘official’ power quality events such as sags/surges/interruptions.

Fault Level (optional): ½ cycle Peak Fault Level, RMS Break Fault Level at 50-90ms and ½ cycle Downstream Motor Contribution. Results dependent on presence of abrupt voltage induced current disturbances > 0.15%.

Configurations: Space for over 200 files. These may be used for configuration or recording sessions.

Accuracy*: 0.2%. 0.1% in reference range 20-30°C (excluding sensors). +/-2LSB.

Resolution: Programmable to 0.1 Vac and 0.1 Aac, 0.01V high resolution mode.

General Parameter measurement: Records automatically. Fixed functions recorded on (selected) intervals. (1 sec to 2 hours). Voltage & Current RMS (Max, Min, Avg). THD / Harmonic Value (8 inputs), Flicker (3 Voltage inputs). Power (kW, VAR, AP, PF), Individual Harmonics 2-50 (8*50 signals on Volts and Current) or optional choice of 2-100 (4*100 on Volts or Current). Unbalance.

Troubleshooting Maths Functions:

AC Single Phase Installation: RMS, Stray Voltage RMS Hi Res < 35V, (line-neutral, line-line where appropriate). Real power W, Reactive Power VARS, Apparent Power VA, Power Factor PF, Displacement Power Factor, Phase Angle, Frequency, Instantaneous Flicker Sensation, Short Term & Long Term Perceptibility, Flicker Flag, Distortion Power.

AC 2 (split) Phase Installation: Real Power, Reactive Power VARS, Apparent Power, Power Factor.

AC 3 Phase Installation (Delta, Wye and variants): Real Power, Reactive Power VARS, Apparent Power, Power Factor, Voltage Unbalance, (Conventional & Sequential Components), Current Unbalance. Distortion Power, Positive Sequence Fundamental Real & Reactive Power (IEEE1459).

Harmonics: Odds, Evens, Triplens, Individual Harmonics value to the 127th and % and Harmonic Direction to the 50th, K Factor, % Total Harmonic Distortion, Total Harmonic Value. Interharmonics.

Advanced Harmonics and Interharmonics Option: Automatic and simultaneous measurement of harmonics*1 to the 100th on 6 inputs (V & I), and to the 50th on remaining 2 inputs as well as individual inter-harmonics between fundamental and second harmonics and inter-harmonic sub-groups to the 100th (3 x V only). Individual harmonics, inter-harmonics, groups and sub-groups to the 127th harmonic on any phase can also be measured on detailed Adaptive Store channels. THD and THC also available to the 100th Harmonic.

*1 As required by the EN61000-4-7 and G5/5 Standards, harmonics recorded as General Parameters are Harmonic sub-groups comprising the Root Sum Square of the harmonic itself plus the two adjacent 5 Hz lines.

Symmetrical Components: Positive, negative, zero sequence: NPS, NPS/PPS (Voltage and Current), ZPS, ZPS/PPS (Voltage).

Other Maths Options: Channel X * Constant, Channel X / Channel Y, Filtered Channel X, Internal Temperature, On Charge, Battery Volts.

Waveform Capture: Sample rate – up to 1.2288 Ms/s in the PM7000T (~ 24,576 samples/cycle at 50 Hz) on 8 channels. Events examined, Ranked & stored in real time.

Selectable waveform parameters:

Wave Retention Basis: Greatest disturbances (automatic ranking and low rank discard) and first past a threshold.

Capture wave bracket: Wave Sets: from 20ms up to 60secs. Can be contiguous; no re-arming.

Signals to be captured: offending wave / complementary current or voltage, All Voltages, All Currents.

Triggers to be used: Transient, Ring, Notch, Sag, Surge, THD Volts, THD Current.

Wave Allocation: Waves allocated across trigger functions.

Sampling: PM7000T (Turbo) 1,228.8k Samples per sec Also records automatically at 60Hz.

Frequency: Automatic frequency tracking in 50 or 60Hz regions. Normal range 45-64Hz.

Dual /Fast Frequency (Optional): Independent frequency variation measurement on V4. Resolution to 0.001Hz (frequency), single cycle (time), latency ~3 cycles. FFR (V4) measurement range 40-70Hz.

Memory: 128MB Flash memory for all files. 32MB RAM for high speed waveform capture data, 64MB working RAM. Expansion with USB Memory Device.

Firmware (program memory) – Flash upgradeable 2MB

User Preferences – Stored in non-volatile Flash Memory.

Portable Device Requirements for PMScreen and PMGateway: Android or Windows compatible.

Data Retention: During recording sequential data is saved to Flash memory. Waveform capture data is held in RAM and transferred to Flash memory when recording ends. Configurations etc. stored in Flash memory.

User Interface via remote screen: PC via Bluetooth or USB running PMScreen, or tablet/mobile phone/netbook (provided) via Bluetooth running PMScreen. Setup/Configuration and Data Review via remote screen. Data analysis using Pronto for Windows. Automatic download to USB stick.

Displays On PMScreen: Power & Energy, Waveforms, Harmonics, Phasors, Harmonic Phasors, Trends, Statistics, List of Channels. Comparison to Standards. Interharmonics (optional).

Communications:

Bluetooth: Wireless interface (isolated).

PMGateway App.: Enables Android mobile phone to act as a Gateway. Send data files to your inbox, start and stop recordings.

USB: Memory module interface (non-isolated).

USB: Serial interface to PC (isolated > 2.5kV) download to PC & control through Pronto for Windows.

Ethernet: Connectivity through local network. Download to PC. Compatible with iHost.

Protocol: MODBUS ASCII.

Power: Requires 100-600 VRMS, 15 W Max from Phase A voltage measurement (40 – 64Hz Rated power consumption 11Watts) or separate power supply at 12Vdc, 6 W.

Burden: Normally <10 VA from Phase A. If a charger is used the Power Supply is automatically disconnected from Phase A (input impedance per phase 32MOhms).

Battery Capacity: 2100mAhrs (5 HI-Temp NiMH batteries).

Battery Ride Through: Ten minutes at a time.

Charge Method: From V1 input or from 12V Wall Charger (auto switching).

A/D Converters, 2 sets: (i) 24 bit at 19.2 kSps, top 16 bits used normally for harmonics, power & energy, Flicker. (ii) 12 bits for High Speed and Turbo only.

Measurement & Reporting Standards: IEC 61000-4-15, IEC 61000-4-7, IEC 61000-4-30, IEEE1453 (Flicker), IEEE1459, IEEE100, Report to EN50160.

Safety Standards: IEC 61010, (600v Cat. IV, pollution level 2, 1000V CAT III if PSU fuses removed), CE Fused voltage leads (lead fuses 500mA, 700V, 50kA rupture current), IEC 61326 (EMC).

Internal fusing: PSU (x2), Charger input, Battery stack, Internal Thermal Switch (x2).

Computer Requirements for Pronto Software: Windows 2000, XP, Vista, 7; 250MB hard drive space.

Case: Pelican 1150 Guard Box: Dimensions. 22.9 x 19.1 x 11.0cm.

Weight: 3.5 kg. without leads and clamps.

Operating Temp: -20ºC (-4º F) to 60ºC (140º F).

Environmental: IP65. Main unit will tolerate momentary emersion when lid sealed. Leads and their connections are not watertight and for safety reasons we strongly recommend that the operator does not connect and disconnect the unit in wet environments.

Applicable Patents: 6424277, 0230712, 4910692.

Measurement & Reporting Standards: IEC 61000-4-15, IEC 61000-4-7, IEC 61000-4-30, IEEE1453 (Flicker), IEEE1459, IEEE100, Report to EN50160.

Safety Standards: IEC 61010, (600v Cat. IV, pollution level 2, 1000V CAT III if PSU fuses removed), CE Fused voltage leads (lead fuses 500mA, 700V, 50kA rupture current), IEC 61326 (EMC).

Applications include:

Trouble shooting unknown power quality issues – Our unique recording regime Adaptive Store is especially useful for identifying and locating problems on your network, recording down to a single cycle the instant events occur without setting any thresholds. Unique precise capturing of sudden changes eg. transients, current spikes, harmonics, drop-outs and brown-outs to extremely high resolution makes detecting problems on your power distribution system easier. The PM7000 is often used when other units without this capability have failed to find a problem.

Real time troubleshooting – Live results, harmonics, waveforms and EN50160 comparisons can all be viewed on an Android tablet or mobile phone via Bluetooth comms even whilst background recording is taking place. Get a head start on your site analysis right from the word go.

New Equipment Installation – Benchmark before and check after the installation of new equipment to ensure quality of service has been maintained.

Power Quality Surveys – record all parameters and create necessary graphs and tables to create your own professional reports. >470 channels are measured in General Parameters to ensure nothing is missed during each recording. Measure all parameters needed for a G5/5 survey to the 100th including automatic and simultaneous measurement of harmonics to the 100th on 6 inputs (V & I), and to the 50th on remaining 2 inputs as well as individual inter-harmonics between fundamental and second harmonics and inter-harmonic sub-groups to the 100th (3 x V only).

Long term monitoring – Discover solutions to hard to find or intermittent problems. Record indefinitely in FIFO mode until the event occurs again. If required download each recording automatically to a hard-drive or memory stick or transfer data via Wifi/3G/4G using our PMGateway App or Ethernet. Discounts available for long term hire.

Speed up critical equipment recovery – Monitor important equipment to capture power quality events if and when it malfunctions. Use this information to get it back online more quickly.

Harmonics Analysis – Monitor harmonics to the 100th on 6 inputs (V & I), and to the 50th on the remaining 2 inputs as well as individual inter-harmonics between fundamental and second harmonics and inter-harmonic sub-groups to the 100th (3 x V only). Individual harmonics, inter-harmonics, groups and sub-groups to the 127th harmonic on any phase can also be measured on detailed Adaptive Store channels. THD and THC also available to the 100th Harmonic. Make an assessment of your site conditions whilst checking compliance with the standards. G5/4 reporting with just a few clicks available since April 2016. Templates for G5/5 data collation available upon request. Outram report writing services also available.

Customer complaints – Solve customer complaints including voltage or flicker problems using the ability to compare any data streams on the same graph in the Outram/Ranger Software, Pronto. E.g. RMS voltage and instantaneous flicker sensation (and any others) on the same graph. Finding the problem quickly using Adaptive Store recording regime means minimum customer disruption.

Measure in remote locations – Automatic restart when power returns if unit is being powered off voltage measured.

Load Distortion and Imbalance

Preventive Maintenance – keep a track on your power quality to detect any problems before they cause your equipment damage or end up in costly down time.

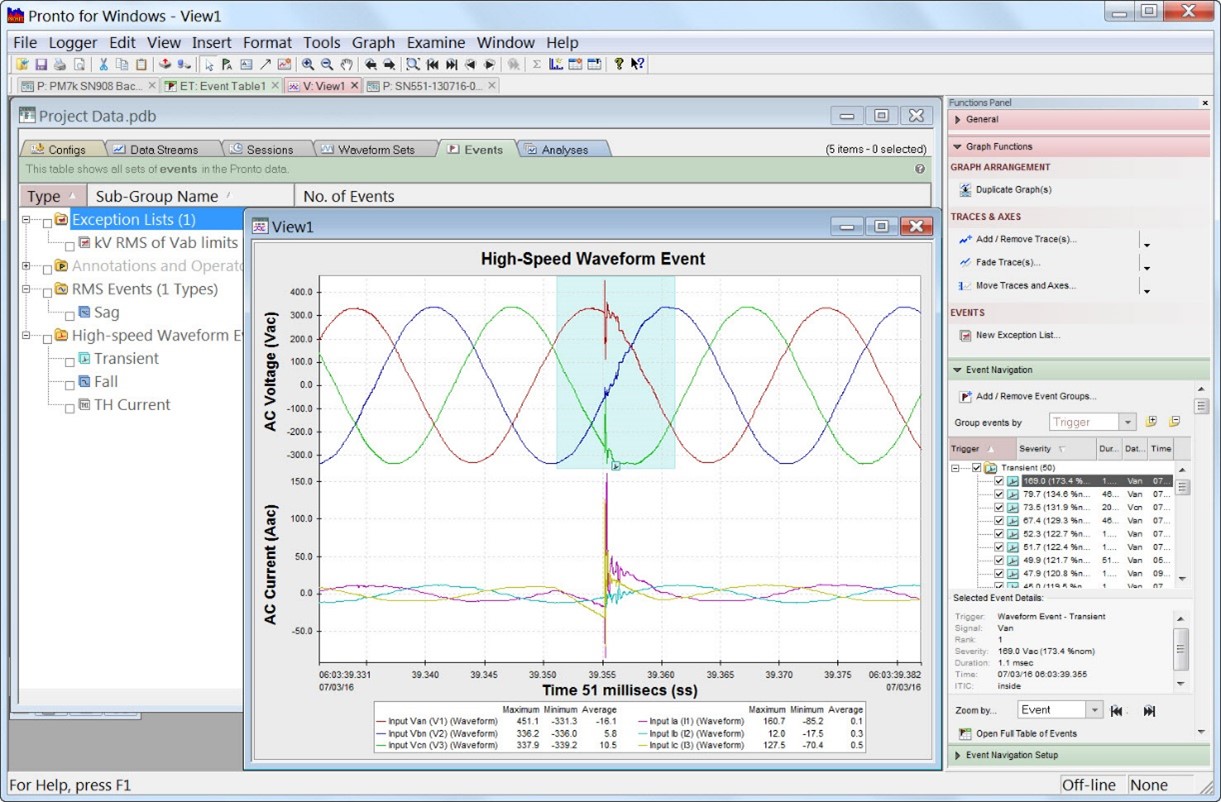

Fast Transient Capture – waveform capture to 1.228MHz with automatic ranking in Pronto to help you zoom in to the most important waveforms in the recording in seconds. Sags, Surges, Transients, Rings, Notches, THD, TH Current are all triggers.

Network Characterization – measure non-sinusoidal and unbalanced systems.

Power Quality Software: Our comprehensive and very flexible Pronto software is the same for all Outram/Ranger Equipment so even when hiring a variety of models you will still use the same software each time.

Recent hire applications include:

- Troubleshooting solar farm commissioning issues

- Solving connection problems at a grid tied Combined Heat and Power Plant (CHP)

- Instability issues on wind farms

- Effects on power quality of malfunctioning large materials handling systems/Cranes

- Monitoring switchover from live to backup power and back again

- Measuring either side of a UPS – Differential inputs allow simultaneous measurements to asses UPS quality

- Determining whether power quality issues are being imported or exported

- Measurement of capacitor switching.

- Ranger PM7000 Power Quality Analyser

- Four 24″ 6000 Amp Flexible Current Clamps(max conductor size 8″), braided

- Five Voltage Probes 600V Cat IV (1000V Cat III),braided, with 5 Voltage Extension Leads

- Three Neutral Common Leads

- Mains Lead and USB Lead

- USB Memory stick for additional memory storage

- Pronto for Windows Analysis Software

- Customer CD with Operation Manual

- Hook-up Checklist and Configuration Guide

Three Different Recording Regimes

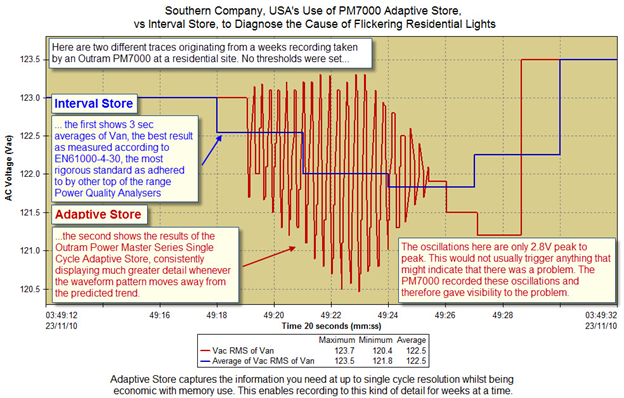

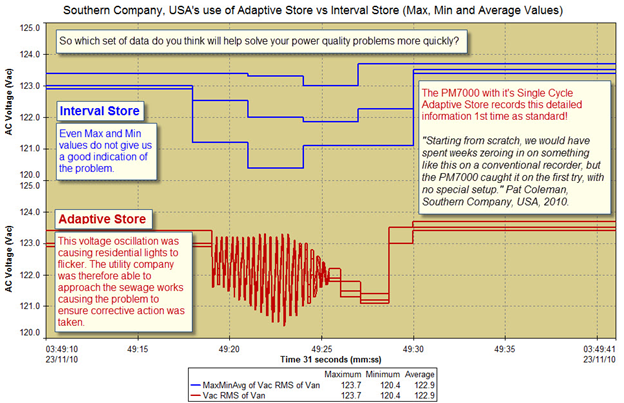

This is the information storage technique used on our 32 detailed recording channels. During the recording the PM7000 automatically alters the detail of the recording whenever a disturbance occurs i.e. whenever there is an anomaly in the recording. This means that when nothing ‘interesting’ is happening the PM7000 does not record every cycle but gives the average, max and min during that period. When something ‘interesting’ happens the analyser records in much greater detail, down to a single cycle, without the user having set thresholds. This makes analysis of the recording much easier and faster, being able to zoom into the causes of power quality problems much more quickly and easily.

Using Adaptive Store is considerably faster and simpler than setting and adjusting trigger levels as required by other power quality monitors: a process that can lead to an operator taking weeks to ‘zero in’ on the problem, as well as needing to wade through much unnecessary data.

Please read our press release for the specific application.

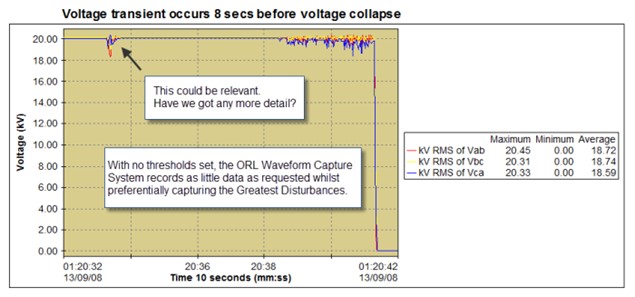

This Auto-Ranking Waveform Capture system automatically keeps the sub-cycle waveforms of the most serious events captured during a recording, discarding the least important, without the need to set any thresholds. The user can choose how many waveforms he wants of 7 different types of event on each detailed channel measured and just get the worst ones most likely to be the cause of his power quality issues. This saves a lot of time and effort analysing the data.

Application for Auto-Ranking Waveform capture – See below how a captured disturbance led to solving a problem?

Could this short lived transient have caused the voltage collapse which came 8 seconds later?

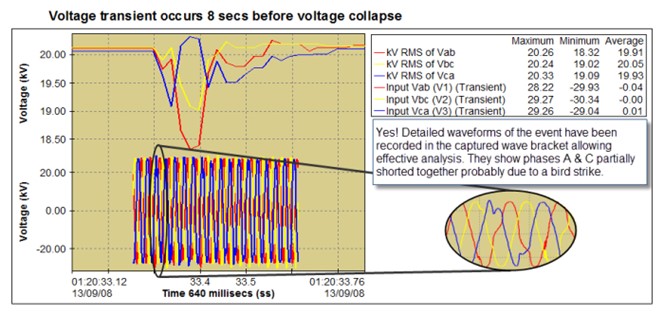

We can zoom in and see that the waveforms corresponding to the voltage transient have been captured, giving us a useful picture of what happened to the different Phases. With the PM7000 you can zoom straight to the problem without having to trawl though mountains of data.

Waveform recordings are continuously re-triggerable and do not require re-arming, so no data is missed.

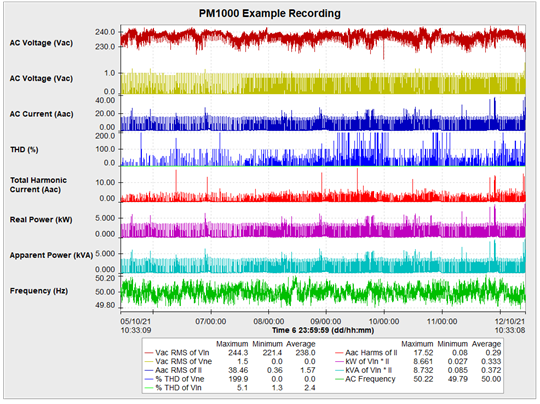

Over 470 parameters are recorded at a specified interval during every measurement, automatically without any user input. This increases to 1000s with our Advanced Harmonics option, measuring all individual harmonics to the 100th on 6 inputs (and to the 50th on the other 2) as well as sub group and interharmonics (more detail below). If a user forgets to specify a particular parameter on one of the detailed channels mentioned above (Adaptive Store), there’s no need to worry as it will very likely be measured automatically in General Parameters. This reduces the need for repeat recordings, saves time and gives a large amount of trend data on a user or their customer’s site without any further thought from the user.

Software

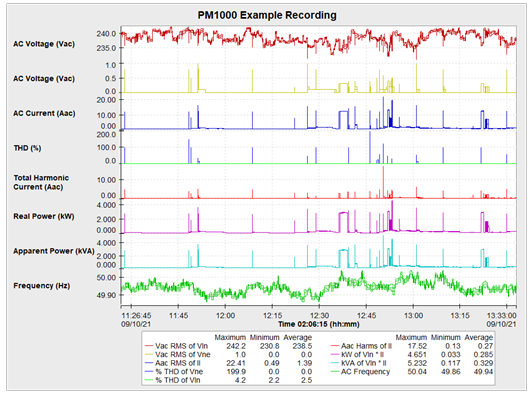

We believe that Pronto is the most comprehensive Power Quality Monitoring Software in the industry. It is well suited to basic compliance testing of data as well as more detailed analysis work. The power and flexibility of the software soon become apparent when the user zooms in quickly to data of interest to then view and present any combinations of data in a clear and concise fashion. The user can easily export tables, copy and paste graphs, add in and remove data parameters quickly and efficiently, as well as effortlessly create templates for both tables and graphs.

Pronto has been developed by Outram Research over the last 30 yrs, originally designed for the process industry. Not only can it manage the data recorded by our PM7000 models but it organises effectively the data downloaded from the whole range of Outram Power Quality and Fault Level Monitors including our single phase PM1000Mk2 to our PM7000T (sampling at 1.228 million samples per second).

It is VERY Flexible. The user can do a lot with the data, including the automatic joining together of distinct recordings, and show data from different Power Master Analyser models on the same graph when measuring around the same time.

What makes Pronto unique is the fact that no, or very few, associations have been made regarding any streams of data recorded. Power Quality data logged by the Power Master Series (including thousands of parameters) can be presented in a very large number of different combinations, making manipulation of the data easy for the user. Data from different Power Master or Ranger models can be viewd together for easy comparison. We understand that our software is also significantly faster to draw than other products, making a large difference to the time spent analysing data.

Nine different parameters presented on the same graph to enable easy comparison of each parameter with any other.

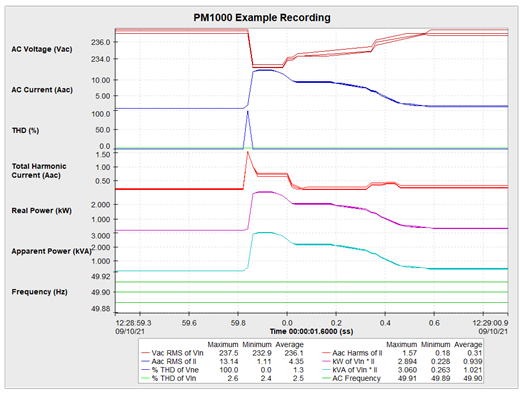

Zoomed in on the graph above, we can see the detail captured on each parameter recorded.

Zooming in more shows the detail captured on each parameter recorded down to single cycle.

The majority of these current spikes and associated voltage dips last less than a second but it is possible to see exactly what is happening. In fact there are around 4 different fridges in use in this recording and each one can be identified by its profile captured by the PM1000 with the same measurement technique also used in the PM7000HF but over 3 phases.

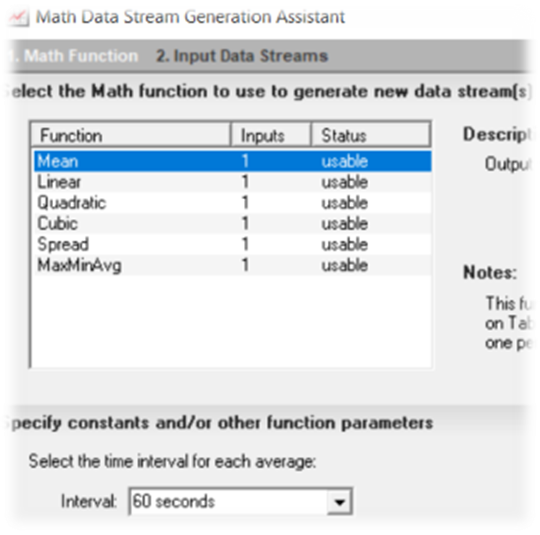

The user can also create Maths data streams using any recorded parameters. They can create averages over 30 sec, 1 min, 5 min, 10 minutes (or in fact any integer time span you choose) which can then be viewed on a graph. (They can also be tabulated). It is possible to choose from any of the maths functions seen here:

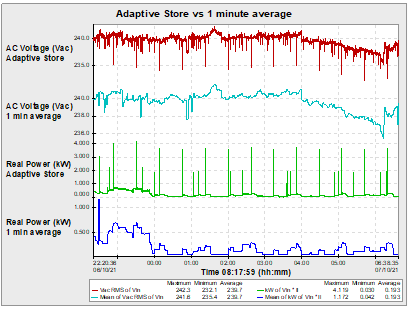

Showing the averaging function used in Pronto (1min averages vs Adaptive Store), is another reminder of how important it is to record that single cycle detail in order to carry out the most useful data analysis possible.

Data Visualisation

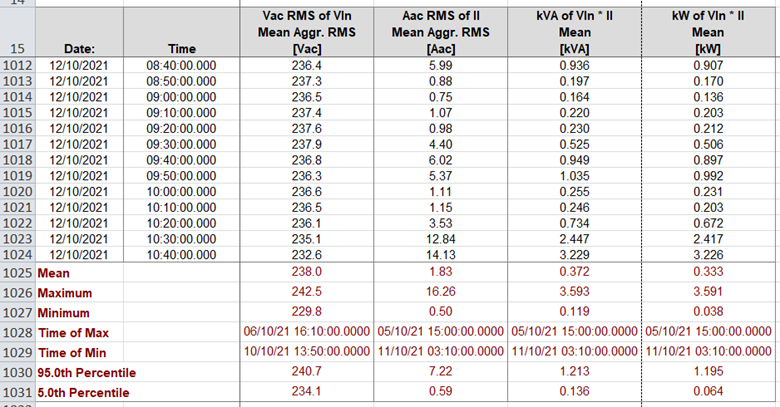

Create tables in Pronto of all the data captured (exportable into Excel and PQDif) and choose how the data is presented. Whether you choose an average over a period to report against the Standards or other options, you can also include the max and min (with times), the mean, 95th percentile, 5th percentile (percentiles are selectable) in a summary section in your table… there are a huge number of possibilities.

Below is a table of data measured using Adaptive Store, averaged over 10 min intervals (rows 16-1011 are hidden in this case), with the mean, max, min and 95th and 5th percentiles.

If you would like to be able to recreate your graph or table, save it as a template to create it again with minimal clicks from the data in your next recording, including formating and title.

Our PM7000 range can also measure 1000s of General (Interval) Paremters as well as carry out Auto Ranking Waveform Capture.

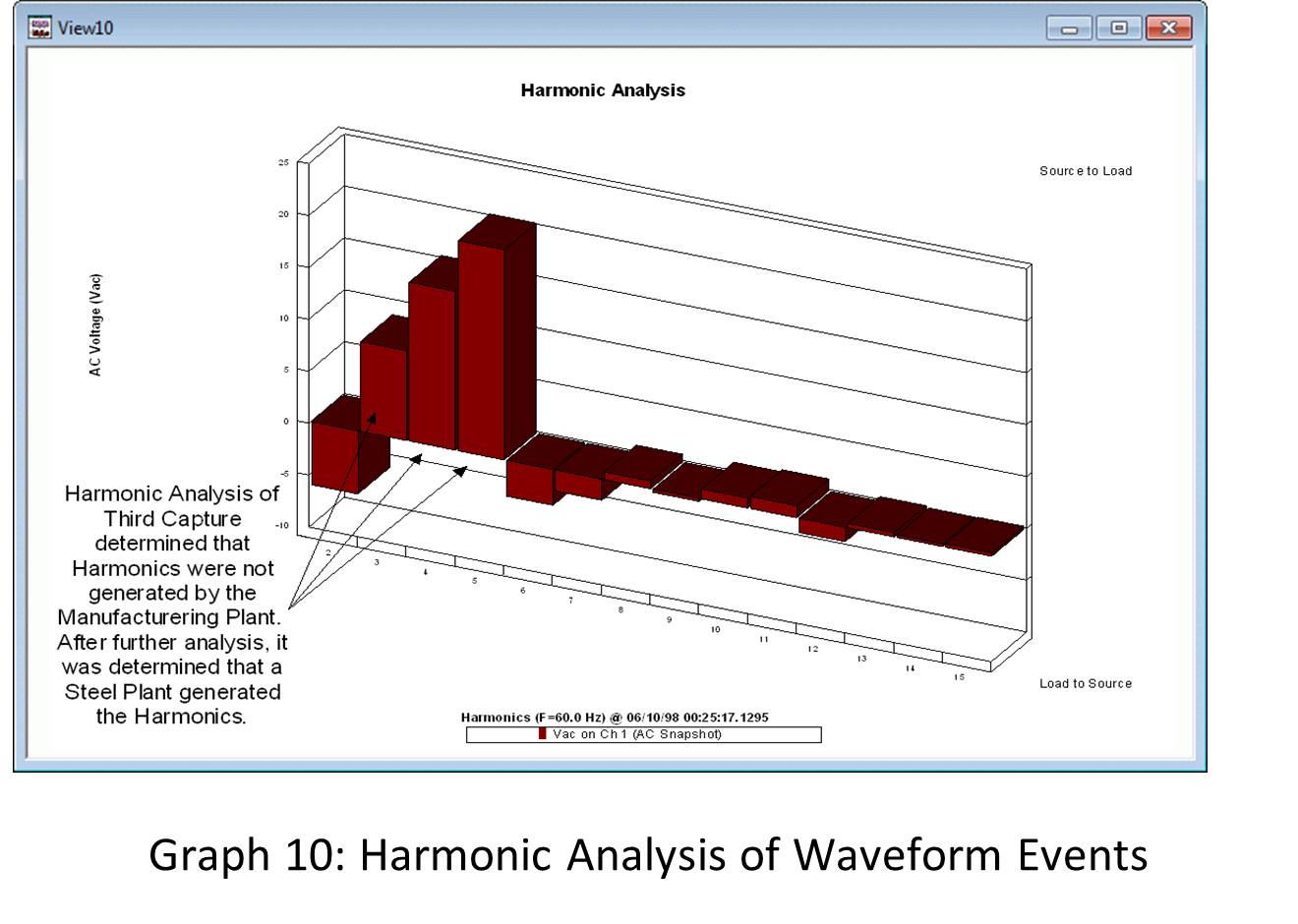

Pronto can present harmonic analysis of captured waveforms, in some cases displaying the apparent direction of those harmonic sources.

Create an extensive Harmonics Survey Report with a few clicks using our G5/4 Reporting function. We use this as the basis for reporting to the updated G5/5 harmonics requirements so it’s a great tool for whatever reporting requirements you have.

We also have tutorials to help users quickly get up to speed with enhanced features of the software. You can find more at

Graph zooming and panning without changing cursor types

Quickly zoom and pan around your graph without using the toolbar or graph menu to swap cursor types.

Templates (1 of 3) – Creating/using view (graph) templates

Save your favourite graphs (with all formatting and setup) into view templates that can be applied to new data with just a few clicks.

Templates (2 of 3) – Organising view templates

Rename, delete and move into folders. Organise your favourite view templates in an easy to use browser. Also find templates on your hard drive to copy to other computers.

Templates (3 of 3) – Editing/Duplicating templates

Edit an existing template and see how to create a new template based on an existing template but for different data streams.

Advanced Harmonics & Dynamic Containment

With our Advanced Harmonics upgrade PM7000 users can measure individual harmonics up to the 127th order as well as Interharmonics and Sub Group Harmonics. Interharmonics are important when measuring the disturbances generated by appliances not related to the mains eg. Mechanical or electrical resonance.

The PM7000 has automatic and simultaneous measurement of harmonics(1) to the 100th on 6 inputs (V & I), and to the 50th on remaining 2 inputs as well as individual inter-harmonics between fundamental and second harmonics and inter-harmonic sub-groups to the 100th (3 x V only).

Individual harmonics, inter-harmonics, groups and sub-groups to the 127th harmonic on any phase can also be measured on detailed Adaptive Store channels. THD and THC also available to the 100th Harmonic.

(1) As required by the EN61000-4-7 Class I and G5/5 Standards, harmonics recorded as General Parameters are Harmonic sub-groups comprising the Root Sum Square of the harmonic itself plus the two adjacent 5 Hz lines.

Our Dual Frequency option adds an additional, independent, precision frequency measurement to a PM7000/ PM7500 with resolution to 0.001Hz used in conjunction with our Dynamic Containment seamless hourly data download facility to allow the user to fulfil their requirements for National Grid (UK)’s Dynamic Containment Monitoring

Although analysers adhering to the standard IEEE1453 (based on IEC61000-4-15) provide adequate Flicker measurements, the Outram PM7000 was the first analyser to also include the required Instantaneous Flicker Sensation output. Instantaneous flicker sensation is the intermediate result needed to produce the averages required by the Standard, and since we are the only design house with the recording mechanism Adaptive Store, mentioned earlier, it can be brought forward to be viewed as live results, by the user.

Read Our Reviews

Trustindex verifies that the original source of the review is Google. I have had the pleasure of working with the Outram's and their Instruments for over 15 years. Their equipment and hire service has never failed. The technical support is second to none and their friendly approach is always appreciated. I have used many alternatives, but for my needs the Ranger PM equipment is the best by far.Trustindex verifies that the original source of the review is Google. I needed soem support with my Outram kit, and got it within minutes! Can't fault any of them team, but special thanks to Kate for helping me. May i have many more years of service on my PM3000!Trustindex verifies that the original source of the review is Google. Fantastic equipment. Brilliant onsite support with their G5/5 and Fault Level Monitor equipment.Trustindex verifies that the original source of the review is Google. I have used Outram Research previously for Power Quality Surveys and G5/4 G5/5 compliance issues. All reports were well presented, on time and well laid out technically. Staff are approachable and customer friendly.Trustindex verifies that the original source of the review is Google. Whilst under contract to Network Rail [RIDC] Midlands Test Facility at Asfordby, Leicestershire. I was required to investigate the impact on Power Quality of the 25kV Traction Testing being undertaken. I researched suppliers of Power Quality Equipment and on discovering the involvement Outram Research Ltd has with the Electricity Supply Industry I recommended NR engage them to assist in the data collection focussed on NPS [voltage unbalance]. I found that Outram Research had a very thorough understanding of all the issues associated with Power Quality and could supply and connect the appropriate Outram Data Loggers to enable the capture of the data I required. With the data captured I was able to demonstrate the .25kV traction testing imposed far less voltage unbalance on the 132kV network than the DNO anticipated. All the Outram staff I engaged with were extremely knowledgeable not only in the data loggers but also in their application. Outram Research downloaded and filed all the data in a logical manner mailing me the information. I have been so impressed with the company and staff that I recommended Outram Research Ltd to the Network Rail Power Quality department describing my experience with them. R H King. C.Eng MIET PowerPhase Services Ltd.Trustindex verifies that the original source of the review is Google. Have used Outram equipment for a few years now, for power quality investigation work and G5/4 and G5/5 surveys etc. It is quality kit and with good analysis software. There is also a version capable of fault level monitoring. Most of all, a great company to deal with and fantastic support.Google rating score: 5.0 of 5, based on 7 reviews